Coil Winder Machine

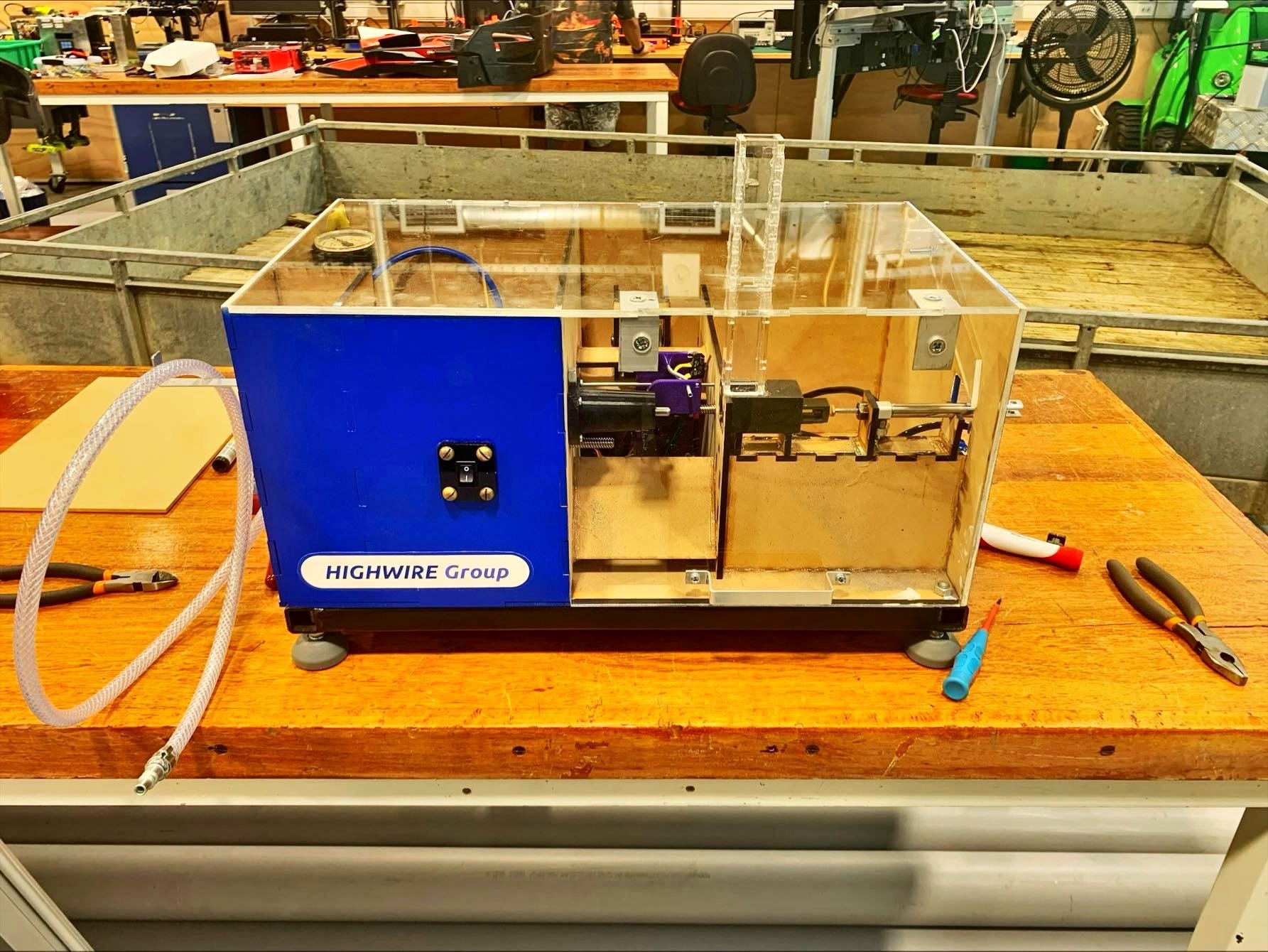

A Prototype designed and made as part of my engineering studies, to be a automated machine that winds copper coils, which is very important for electronics, that minimises the amount of human involvement in making copper coils.

Year

2022

Task: Automating Coil Winding

Coil winding is the method where cooper coils are made, and they are very important in electronics, as inductors and motors needs copper coils to function. There are many machines that already exists, but they all involved human interaction to some degree, with some require large amount of human action, to mount the spool, to set the wire, to cut the wire at the end, and to fix the coil, etc, and many with greater degrees of automation. This project aims to prototype a machine with a greater degree of automation, to serve as a replacement of a current machine with a fictional company, and to determine whether or not it would benefit the company to buy the new machine.

Process: Design and Improvement

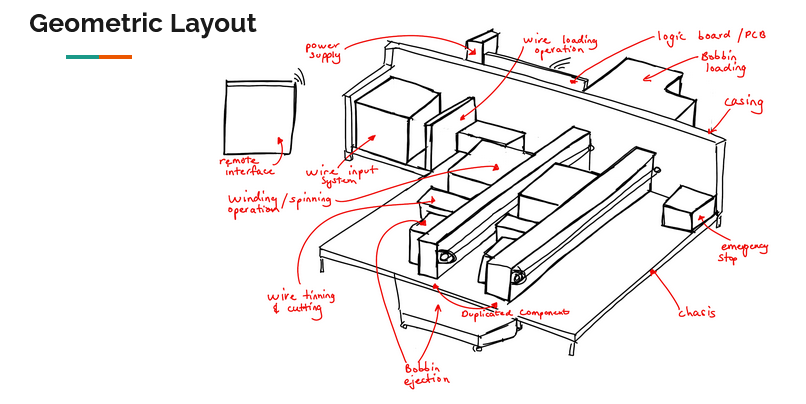

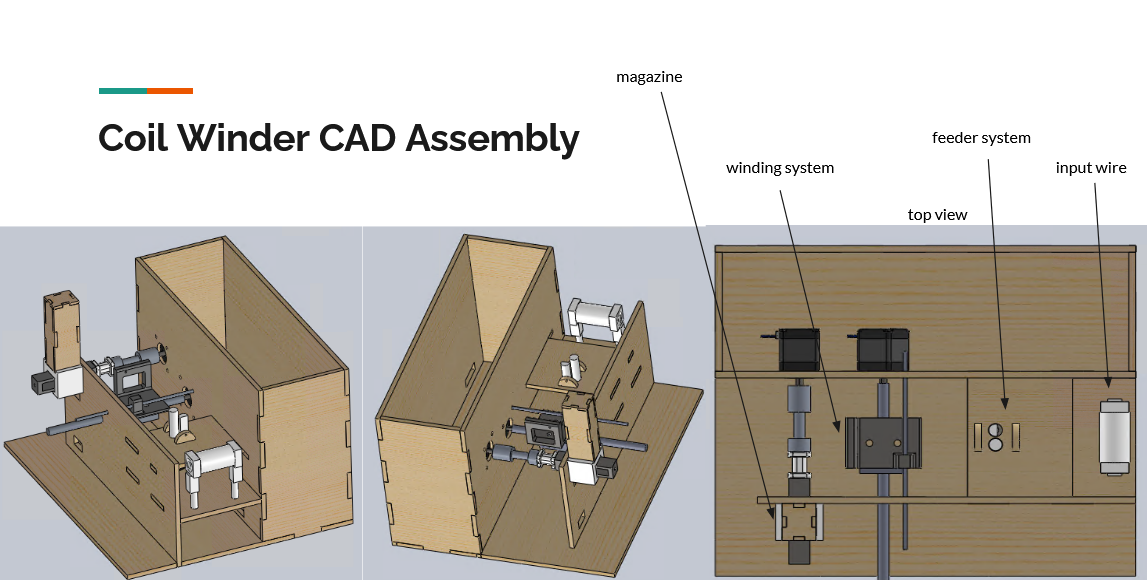

The design of the machine was done via a standard product development process called the stage gate process, and concepts are generated after some initial research. After the concepts were generated, specifications were set for it, with the amount of automation being set to as much as we could do, with a automatic loader and automatic un-loader. The design was also divided into modules, with a wire cutting module, a loader/ unloader module, and a winder/spindle module.

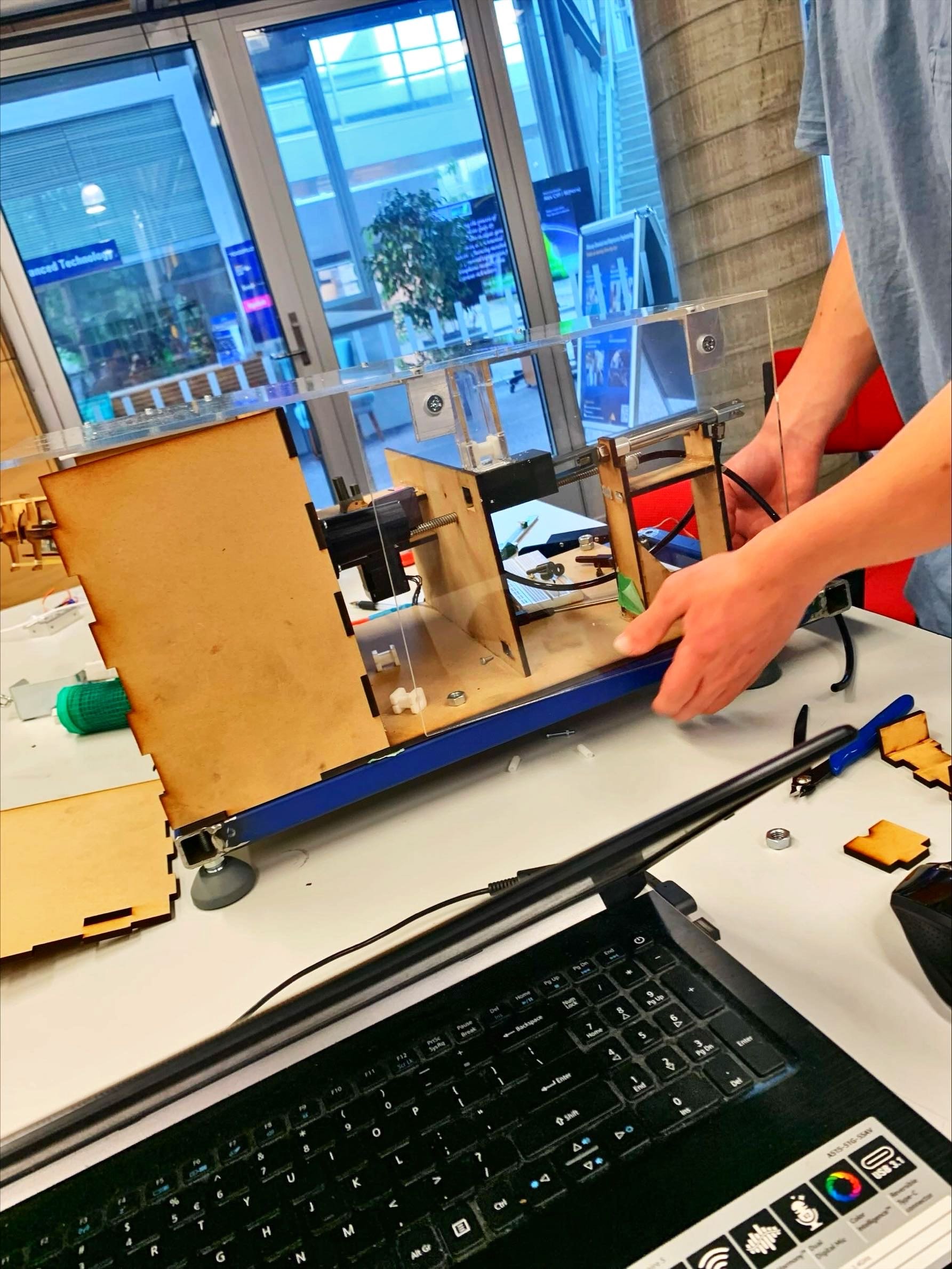

As more information became available, the design became better defined and then finalised into the prototype that was made. This combined the models of the different modules from before, and have them set in a fixture. By using CAD models, the modules could be designed to interact together without having to made and done via trail and error. The design was made using MDF for the fixture, for the ease of use pair with laser cutting, sitting on top of a rectangular base made of steal square tubes, and with a cover made from polycarbonate sheets for safety.

Results and Conclusion

This machine, as the group has concluded ad the end of the project, is that it would be worthwhile for our fictional company to continue to develop, as the design is technically and financially feasible, and would be a good replacement for the current design with better features. The prototype is not a finished product, and it will require more work for it to be a marketable product, with further development and working through it’s teething issues.

Overall, from this project, many key lessons on team work, project planning and technical knowledge was learnt, and this is a good demonstration of what a 2nd year Mechatronics Engineer should be able to do. This was a key learning experience for me, and I have been able to improve in my technical know-how, as well as my ability to work as part of a team, to succeed in more complex and difficult projects.